Static Control for Hazardous Areas

Supplying static grounding and bonding solutions to hazardous area HAZLOC / Ex industries, providing a safer working environment.

Leading the way in static grounding solutions for over 40 years

Hazardous area operators will be all too aware of the danger static electricity poses. Discharges of static electricity have been identified as the ignition source in a broad range of processes, posing a substantial risk to people and plant.

At Newson Gale, we manufacture products to assist with static ground monitoring and control in hazardous locations.

Based in Nottingham, United Kingdom, we supply static earthing solutions and grounding equipment, to companies worldwide via offices in the UK, USA, Germany and China, and a network of channel partners, to keep you, your workforce, and your facilities safe from electrostatic sparks.

Our Earth-Rite range of static grounding and interlock systems provides the most comprehensive protection against electrostatic ignition hazards.

Are you protected from the dangers of static electricity?

Static Grounding Solutions from Newson Gale

Earth-Rite® Systems

Our Earth-Rite range of static grounding and interlock systems provides the most comprehensive protection against electrostatic ignition hazards.

Bond-Rite® Clamps

Our Bond-Rite® range of static grounding systems with visual indication provides protection and increased safety over electrostatic hazards.

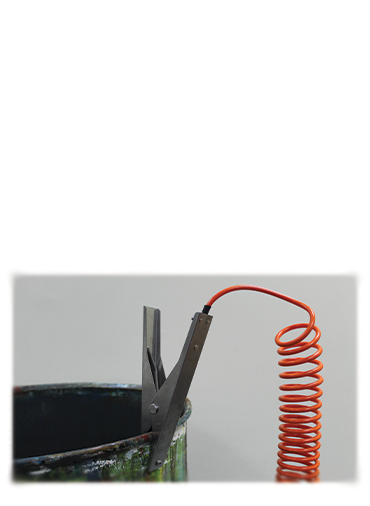

Static Grounding Clamps & Cables

Cen-Stat™ static grounding cables, clamps and reels provide the most basic form of protection against static hazards.

Testing Equipment

Our range of testing equipment ensures the products are working correctly protecting people and plant equipment.

Mobile Solutions

Our mobile grounding solutions provide an automatic confirmation of a good connection between mobile vacuum trucks and a metal object in the ground to ensure safe operation.

Dual Core Clamps

Our dual core grounding clamps ensure a good low resistance connection to the metallic object and provide a reliable operation for our grounding systems.

Does earthing reduce static electricity?

Indeed, it does. Earthing, grounding and bonding help to dissipate static electricity which can cause a static spark, endangering the lives of anyone working within your facility. Any business that operates within a hazardous environment at risk of static charge should take steps to reduce the danger, increase safety and ensure smooth running operations at all times.

How do you ground against static electricity?

This requires specific ground equipment that is connected to the earth, usually via an electrode or a grounding rod that drains away static charges. This stops the charge from building up and eventually jumping to another object which could result in fires and explosions breaking out.

Is your facility protected from static electricity?

Many industries implement processes as a means to practice compliance. However, it’s vital that your facility goes above and beyond best practice compliance to ensure the safety of workers from the dangers of sparks caused by inefficient grounding, earthing or bonding.

Get in touch with the team at Newson Gale to discover how our products can keep your facilities as safe as possible.

Visit Our Knowledge Hub

Our static control knowledge hub is a comprehensive library of information relating to the dangers of static electricity in hazardous locations. If you are mixing, blending, pumping, or transferring hazardous materials, these articles provide an insight into what practical measures can be taken to mitigate the risk of static sparking resulting in potential fire and explosions within the workplace. Keep your people, equipment, and facilities as safe as possible by visiting our knowledge hub.

Our static control knowledge hub is a comprehensive library of information relating to the dangers of static electricity in hazardous locations. If you are mixing, blending, pumping, or transferring hazardous materials, these articles provide an insight into what practical measures can be taken to mitigate the risk of static sparking resulting in potential fire and explosions within the workplace. Keep your people, equipment, and facilities as safe as possible by visiting our knowledge hub.

New Earth-Rite DGS – Dual Grounding System

Newson Gale is proud to launch the Earth-Rite Dual Grounding System (DGS). Combining visual indication, interlocking capabilities, and two intrinsically safe monitoring circuits, the system is our latest solution for simultaneous grounding for static electricity in hazardous areas.

Newson Gale is proud to launch the Earth-Rite Dual Grounding System (DGS). Combining visual indication, interlocking capabilities, and two intrinsically safe monitoring circuits, the system is our latest solution for simultaneous grounding for static electricity in hazardous areas.

Click to download the full press release and product datasheet

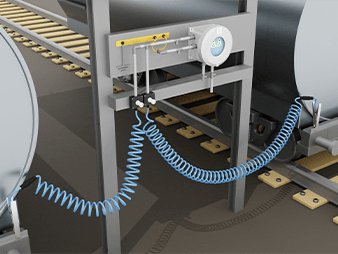

Newson Gale launches new Break-Away Connector

The latest Break-Away Connector from Newson Gale has been designed to help mitigate the effects of a Tank Truck drive off after loading or unloading operations. The Break-Away Connector separates the clamp and cable from grounding system in the event of a vehicle drive off. The clamp and cable assembly can then easily be replaced reducing the amount of downtime which can be costly to the business.

The latest Break-Away Connector from Newson Gale has been designed to help mitigate the effects of a Tank Truck drive off after loading or unloading operations. The Break-Away Connector separates the clamp and cable from grounding system in the event of a vehicle drive off. The clamp and cable assembly can then easily be replaced reducing the amount of downtime which can be costly to the business.

Click to download the full press release and product datasheet

Newson Gale’s products are certified for use around the globe within hazardous area industries.

What is your Application? What needs grounding?

Partner with Newson Gale to keep your operations safe

If you’re looking to improve the safety of your hazardous area through earthing, bonding or grounding devices the team at Newson Gale can help. We can guide you to the right solution to mitigate static ground charges and electrostatic ignition hazards.