Closing the Loop: Static Grounding Best Practices for Railcar Transfer Operations

Introduction to Static Grounding Best Practices for Railcar Transfer Operations

In the hazardous process industries, commonly referred to as the “Ex” and “HAZLOC” industries, static electricity is generated frequently. Various grades of crude oil, refined petroleum products like LPG, and numerous chemicals fall into a category of materials known as “static accumulators”.

During a typical railcar loading operation, the static accumulating product is transferred from a storage tank via a gantry loading system into a receiving railcar. The transfer process electrostatically charges the product as it moves through the pump, filtration, and piping system.

If the railcar is not directly connected to the earth, electrostatic charges accumulate on its surface, causing its voltage to rise rapidly. The tanker then seeks to discharge excess potential energy, with the most efficient method being a static spark.

Energy Discharged in Static Sparks

Grounded objects near charged surfaces are prime targets for electrostatic sparks. Allowing the uncontrolled accumulation of static electricity in an Ex/HAZLOC atmosphere presents a significant ignition risk. If the railcar is ungrounded, its voltage can rise to hazardous levels in a very short space of time.

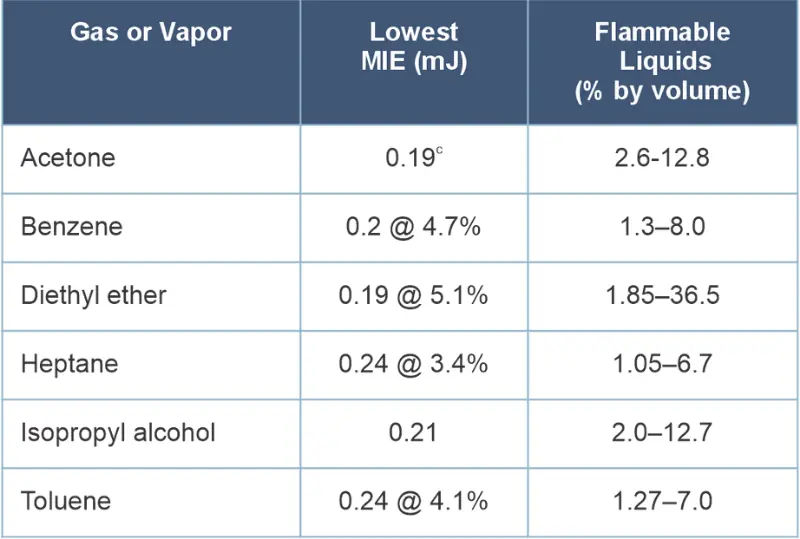

The Minimum Ignition Energy (MIE) is a measure of the minimum amount of spark energy necessary to ignite combustible gases and/or vapors.

The Importance of Bonding and Grounding the Railcar

Comparing the energy of static sparks with the minimum ignition energies of petroleum products and flammable chemicals highlights the importance of bonding and grounding the railcar and connected equipment, such as hoses and piping.

Additionally, at these energy levels, mitigating electrostatic shocks to workers is critical, as involuntary reactions to shocks can lead to accidents, especially when personnel are working at height.

Of the several factors influencing static charging, grounding the railcar is one of the most controllable methods to enforce as part of your Standard Operating Procedure for railcar loading and unloading operations.

Proper grounding helps maintain a low resistance to the general mass of the earth, allowing for safer dissipation of static charges.

In North America, dedicated static grounding systems for railcars are standard practice. In Europe, practices vary; some sites actively ground railcars, while others assume sufficient bonding between the tanker chassis and wheels enables charge dissipation through the tracks.

Industry Code of Practice

In the case of a railcar, IEC TS 60079-32-1 (Explosive Atmospheres: Electrostatic Hazards) recommends that the resistance of the bonded connection between rail tracks and the loading gantry should not exceed 1 meg-ohm.

However, as rail tracks and gantry connections typically involve heavy-duty metal conductors, a threshold above 10 ohms may indicate a potential fault with the grounding circuit.

The National Fire Protection Association (NFPA) provides specific guidance on controlling electrostatic hazards in HAZLOC areas.

- NFPA 77: Recommended Practice on Static Electricity (Chapter 12.4.2) (2024) highlights the risk of non-conductive wear pads and bearings, which can prevent charge dissipation from the railcar tank to the wheels.

- It recommends a maximum resistance of 10 ohms for grounding and bonding circuits.

- The use of interlocks is also recommended to prevent product transfer if the railcar is not grounded The use of interlocks is also recommended to prevent product transfer if the railcar is not grounded.

Specifying a Static Grounding System for Rail Tanker Operations

One of the challenges with static electricity is its imperceptibility. This can lead to a false sense of security among operators conducting railcar product transfer operations. A grounding system that provides a clear visual indication, such as a “GO/NO-GO” signal using a traffic light method of indication, enhances safety SOPs and compliance with best practice.

Interlocking the transfer system with the grounding system adds a level of control. This helps prevent product transfer starting when proper grounding is not established. Newson Gale recommends the Earth-Rite® PLUS for bonding rail tankers to loading gantries. This system is ATEX and IECEx certified for all gas and liquid vapor groups and helps maintain a 10-ohm or lower connection between the railcar and the product transfer system.

When connected, the Earth-Rite® PLUS automatically verifies the continuity between the railcar and the loading gantry true earth ground connection. The system uses a Factory Mutual-approved grounding clamp with tungsten carbide teeth, providing a strong, vibration-resistant connection.

Unlike non-monitored grounding systems that assume static dissipation, the Earth-Rite® PLUS actively monitors the connection using dedicated static grounding terminals. This monitored connection provides a verified grounding path for static charges. Once a secure connection is established, a cluster of green LEDs flashes continuously to indicate active monitoring.

The system also features volt-free double-pole, double-throw contacts that can interlock with pumps or PLCs. If resistance exceeds 10 ohms, the system halts product transfer, reducing static generation and mitigating the risk of electrostatic discharge igniting flammable atmospheres.

Conclusion

Proper grounding and bonding of rail tankers in HAZLOC environments are essential for managing electrostatic hazards.

Best Practices include:

- Using dedicated static grounding systems to provide a monitored, low-resistance connection.

- Following NFPA 77, API RP 2003, and IEC 60079-32 recommendations to maintain resistance below 10 ohms.

- Interlocking grounding systems with transfer operations to prevent loading when grounding is not established prior to product transfer.B

By incorporating these measures into standard operating procedures (SOPs), facilities can mitigate ignition risks associated with static electricity and promote safer railcar loading and unloading operations.