Provides a high-level overview of the key features and benefits of Newson Gale’s range of static grounding solutions.

Provides a high-level overview of the key features and benefits of Newson Gale’s range of static grounding solutions.

For over 40 years, Newson Gale has provided its customers with static control solutions that reflect a standards-based approach to mitigating the ignition risks associated with static electricity in hazardous locations.

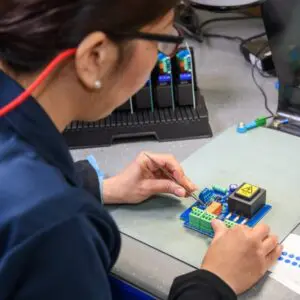

We focus exclusively on the development, manufacture, and distribution of static control solutions that are designed to mitigate against the accumulation of static electricity on plant equipment used in hazardous locations.

Our standards-based approach to the development and manufacture of static control solutions reflects our customers’ desire for implementing hardware solutions that support standard operating procedures (SOPs) for personnel engaged in running processes susceptible to discharges of incendive electrostatic sparks.

The processes that require a hardware solution to support best practice with static control procedures are seen in the manufacture and distribution of potentially combustible products in the petrochemical, specialty chemical, oil & gas, food ingredients, and pharmaceutical industries.

As a manufacturer of HAZLOC certified equipment, our quality management systems are audited on an annual basis for compliance with ISO 9001, and, more specifically, the subset of ISO 9001 that applies to quality management systems for the manufacture of HAZLOC certified products, ISO/IEC 80079-34:2018, “Explosive atmospheres – Part 34: Application of quality management systems for Ex Product manufacture”.

ISO 9001 certificate

We are also subject to regular surveillance audits, ensuring compliance with the global certifications of our products.

As developers of static control solutions destined for installation and operation in hazardous locations, we adhere to global certification requirements. Using OSHA-recognized NRTLs, all Newson Gale HAZLOC products are independently assessed to ensure compliance with all applicable standards that apply to the protection concepts of the equipment.

We support our customers with the Essential Health and Safety Requirements of the ATEX Workplace Directive (99/92/EC) by following the requirements of the ATEX Equipment Directive (2014/34/EU) and the group of EN 60079 “Explosive atmospheres”, product standards that specify the equipment protection techniques that shall be used, in addition to the classification of the hazardous locations in which they shall be installed. Click here to view our selection of HAZLOC-certified equipment.

With the exception of the HAZLOC product certification standards that are designed to mitigate against hardware faults (e.g., electrical arcs/sparks) that could result in potential ignition sources, there are no specific product standards that address the operating parameters of static control equipment.

This is why, wherever practicably possible, we incorporate the recommendations of Technical Specifications like NFPA 77 “Recommended Practice on Static Electricity”, IEC 60079-32-1, and Industry Best Practice guidelines from industry associations like the European Solvents Industry Group into the performance parameters of our products. In particular, IEC 60079-32-1 “Explosive atmospheres, Part 32-1: Electrostatic hazards, guidance” is described as giving:

“… the best available accepted state of the art guidance for the avoidance of hazards due to static electricity” and is “mainly written for designers and users of processes and equipment, manufacturers, and test houses. It can also be used by suppliers of equipment (e.g. machines) and flooring or apparel when no product family or dedicated product standard exists or where the existing standard does not deal with electrostatic hazards.”

If you choose to specify a Newson Gale static control solution, regardless of where you are in the world, our sales team/s and hazardous location experienced engineers will support you with any pre-sales or post-sales inquiries you may have, ranging from the HAZLOC certification details of our products, support with installation and operating instructions, and any technical post-installation questions you may have.

We are confident in the reliability of our static control solutions and offer customers a 7 year warranty against manufacturer’s defects on PCBs and 1 year on mechanical parts. See our Certificate of Warranty page for full details.

With sales offices located in the US, UK, Germany, Singapore & Shanghai, in addition to our network of distributors operating across Mexico, Brazil, Europe, the Middle East, India, South Korea, Australia, and Africa, we can supply you with a common platform of static control solutions that carry the HAZLOC certificates required by your local regulators.

The Break Away Connector (BAC) is designed to address drive-offs during tanker trucks/tank trucks loading and unloading operations. To ensure safe product transfer, the grounding clamp must always be attached to the tanker truck before any other operations begin and securely stowed after all activities are completed. Failure to follow this procedure can result in the tanker truck driving off with part of the grounding system, causing costly damage and lengthy delays in restoring the safety system. The BAC mitigates this risk by allowing the grounding clamp and one-half of the connector to separate from the cable if a drive-off occurs, meaning only the clamp and connector need to be replaced to quickly restore the grounding system.

The Universal Resistance Tester (URT) is designed to provide users of Newson Gale Bond-Rite® static grounding systems with a means of testing the permissive resistance range on a regular basis.

The easy-to-use tester consists of a pair of rotary switches that enable a competent electrical person to check the resistance level at which the grounding system should be working and conduct a PASS/FAIL test at the required setting.

The Earth-Rite® II MGV Tester is a capacitance resistance tester (CRT) designed to have the same electrical characteristics as a tanker truck and provides engineers with a means of checking that the Earth-Rite® II MGV undergoing installation is permissive when it detects these characteristics.

The tester is connected to the Earth-Rite® II MGV system and its grounding point, and when activated, the Earth-Rite® II MGV’s LED indicators change from red to green, confirming that the Tanker Truck Recognition and Static Ground Verification checks are functioning as intended.

The CRT is highly recommended with a minimum of one per site.

• Required for system commissioning and routine service checks

• Easy to use with simple PASS/FAIL condition

Newson Gale’s R-series of static grounding reels offer Hytrel® cable housed on automatically retractable cable reel.

An optional stowage point is available for the VESX50-IP 2 pole magnetic grounding clamp. It allows the clamp to have a designated stowage point close to the item of ferrous metal based plant that the operator can use to stow the clamp safely when it is not in use.

Cen-Stat™ is a range of brightly coloured cables specially designed for applications in industrial and hazardous locations. Cen-Stat™ cables are based upon Hytrel® that combines the flexibility of rubber with the strength and process flexibility of thermoplastics.

Cables made from Hytrel® are mechanically resilient, have a wide working temperature and are resistant to a wide range of chemicals, as well as strong and durable.

The Cen-Stat™ range of FM and ATEX approved static grounding clamps and systems are designed to operate in the harshest hazardous locations. The certifications achieved by our range of clamps and cables benchmark their ability to establish and maintain good electrical contact with equipment requiring static grounding and bonding protection.

Equipment specifiers can order the Bond-Rite® CLAMP with 2-pole Cen-StatTM cable on standard spiral lengths of 10 ft (3 m), 16 ft (5 m), 32 ft (10 m) and 50 ft (15 m) of cable.

The spiral cable retracts when the clamp is not in use, ensuring the cable is neatly stowed and safely out of the way.

The Universal Resistance Tester (URT) is designed to provide users of Newson Gale Earth-Rite® static grounding systems with a means of testing the permissive resistance range on a regular basis.

The easy to use tester consists of a pair of rotary switches that enable a competent electrical person to check the resistance level at which the grounding system should be working and conduct a PASS/FAIL test at the required setting.

With this assembly operators tasked with grounding mobile process equipment will have a dedicated grounding point to attach the easy-to-use screw thread connector. The ‘plug-and-play connector can interface with all Newson Gale 2-core systems to provide ground monitoring capability on a wide range of mobile processes and equipment where generic grounding clamps cannot be used. The conical shape design aids in the reduction of powder deposit buildup over time and aids in clean-down operations.

A quick and easy-to-use grounding kit that may be swiftly deployed in an emergency or combustible material transfer operations where pre-existing designated grounding points are not available or accessible.

The portable grounding kit combines multiple shortened grounding rods (14 inches long) with surface wire grounding techniques to provide acceptably low resistance for static grounding requirements in field operations.

The flexible array of interconnected grounding rods is inserted into the soil at specified intervals to maximize the ability to safely dissipate static electricity from mobile trucks, service vehicles, and other equipment.

Static Grounding Canvas Kit Bag for Portable Grounding Kit and Cen-Stat™ Clamps, Assemblies, and Tools.

The strobe light is mounted in an elevated position and when the equipment is correctly grounded, flashes continuously informing personnel that a transfer process is underway and is protected from the static hazard. The strobe light can be used in conjunction with this product.

Designed for operating environments subject to intense sunlight, the ERII Sun Shield protects against direct sunlight hitting the indicators on the static grounding system.

The Sun Shield casts a shadow over the indicators during peak sunlight hours so that operators can easily view the ground status indicators. The shield is constructed from stainless steel and can be fitted to any installation in a matter of minutes.

The IS Switching PCB is an additional circuit board added to Newson Gale system enclosures, enabling users to directly interface with, and switch, intrinsically safe circuits without the need for additional equipment. The IS Switching PCB is designed not to affect the IS signal’s electrical parameters and is compatible with this product.

The retractable cable reel is supplied for grounding system installations where customers want to ensure the grounding clamp and cable are returned to the static grounding system by operators and drivers on completion of the material transfer process. The reel can be used in conjunction with this product.

The Earth-Rite® II RTR Tester is a capacitance resistance tester (CRT) designed to have the same electrical characteristics as a tanker truck/tank truck and provides engineers with a means of checking that the Earth-Rite® II RTR undergoing installation is permissive when it detects these characteristics.

The tester is connected to the Earth-Rite® II RTR system and its grounding point, and when activated, the Earth-Rite® II RTR’s LED indicators change from red to green, confirming that the Tanker Truck Recognition and Static Ground Verification checks are functioning as intended.

The CRT is highly recommended with a minimum of one per site.

• Required for system commissioning and routine service checks

• Easy to use with a simple PASS/FAIL condition