Static Grounding for Powder Processing Equipment

Mitigating electrostatic charge in powder processing operations

Powder processing operations can generate large quantities of electrostatic charge via the movement of powder. The most common cause behind the electrostatic charging of powder processing equipment is triboelectrification.

In pharmaceutical operations, equipment such as powder conveying systems, micronizers, blenders, and sieve stacks all make up multiple component assemblies that can accumulate high levels of electrostatic charge should any of the components be isolated from a true earth.

In the food, beverage, and pharmaceutical industries, where regular disassembly for cleaning and maintenance is required, it can result in bonding connections being missed or not made correctly when the equipment is reassembled, as well as degradation of assembly connections.

All of this creates isolation from true earth ground, and electrostatic charges are allowed to accumulate to excessively high voltage potential. Regular flexing, vibration, and corrosion can also degrade assembly connections, so it is imperative to ensure that no parts in the assembly become isolated from a true earth ground.

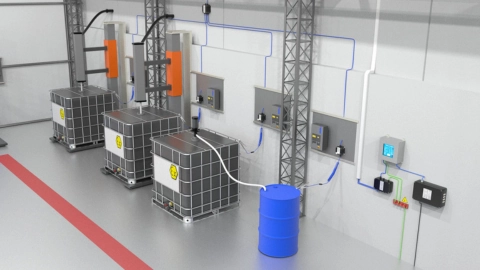

Powder processing equipment presents more of a challenge compared to standard applications, as there are many metal parts that can make up larger assemblies that are potentially electrically isolated from each other. It is therefore important to ensure that multiple components that come into contact with charged powders have a means of being monitored for static grounding protection purposes.

Recommended Solution:

NFPA 77 2024ed Clause 15.6 “Pneumatic Transport Systems” states:

15.6.2

“The construction materials of pipes and ducts used for the conveying of powders should be conductive (e.g., metal) or static dissipative and be grounded.”

15.6.2.1

“Equipment to which the conduits connect should be conductive (e.g., metal) or static dissipative and grounded to dissipate the charge impressed on it by the transport of the material.”

7.3.1.6.1

“Where the bonding/grounding system is all metal, resistance in continuous ground paths is measured to verify mechanical integrity. (See A.3.3.2.) Such systems include those having multiple components. Greater resistance usually indicates that the metal path is not continuous, usually because of loose connections or corrosion. A permanent or fixed grounding system that is acceptable for power circuits or for lightning protection is more than adequate for a static electricity grounding system. Static grounds should be made to the building steel, if possible. Grounding to power grounds or lightning protection systems is not recommended.”

A.3.3.2 Bonding

“A resistance not exceeding 10 ohms for copper wire or 25 ohms for stainless steel or other metals is typically found in practice. Higher resistances could indicate a lack of mechanical integrity.”

NFPA 77, 15.3.1 & 15.3.2 “Mechanisms of Static Electric Charging” states:

“Contact static electric charging occurs extensively in the movement of powders, both by surface contact and separation between powders and surfaces and by contact and separation between individual powder particles… Charging can be expected any time a powder comes into contact with another surface, such as in sieving, pouring, scrolling, grinding, micronizing, sliding and pneumatic conveying…”

IEC TS 60079-32-1, 13.4.1 “The establishment and monitoring of earthing systems” states:

“Where the bonding/earthing system is all metal, the resistance in continuous earth paths typically is less than 10 Ω. Such systems include those having multiple components. A greater resistance usually indicates that the metal path is not continuous, usually because of loose connections or corrosion. An earthing system that is acceptable for power circuits or for lightning protection is more than adequate for a static electricity earthing system.”