Flexible Intermediate Bulk Containers

Flexible Intermediate Bulk Containers (FIBC) are regularly used to store and transport products like powders, flakes, and granular materials.

In hazardous environments, due consideration needs to be given to their use as the movement of such materials into and out of FIBCs can produce electrostatic currents and voltages of magnitudes that are well above the Minimum Ignition Energies (MIEs) of combustible dust and vapors.

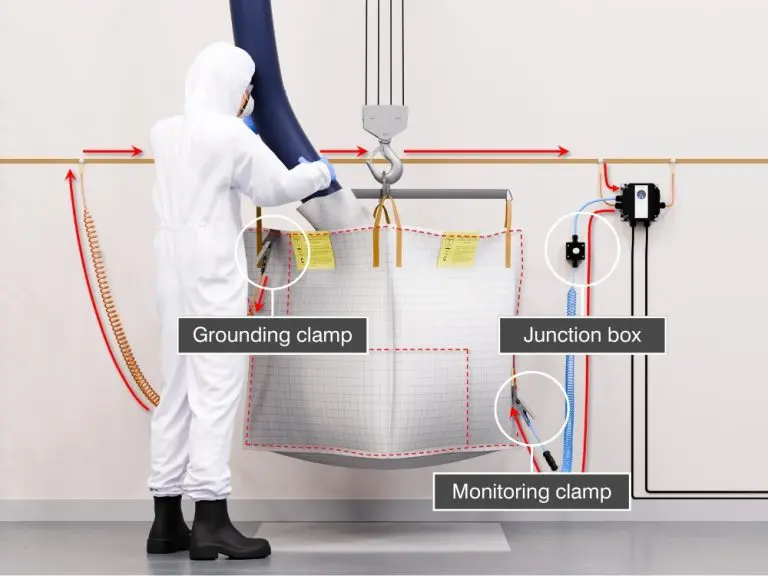

The Earth-Rite® FIBC manufactured by Newson Gale is a static ground monitoring system for filling and emptying Type C flexible intermediate bulk containers (Ex FIBCs).

A product standard published by the IEC, and adopted by CEN (for EN standards publication purposes), addresses the requirements of FIBC used in hazardous locations that range in volume from 0.25 m3 to 3 m3.

This standard is called: IEC 61340-4-4 “Electrostatics Part 4-4: Standard test methods for specific applications – Electrostatic classification of flexible intermediate bulk containers (FIBC)” as referenced in NFPA 77 2024ed, Section 16.6.

As it is not possible to explore the detailed requirements of this standard in depth here, it is advisable to review a copy of the standard if you are using or intend to use FIBC in a hazardous location.

Recommended Solution:

A summary of the IEC 61340-4-4 requirements:

- Classification and labeling of FIBC.

- Classification of inner liners.

- Specification of test methods for each type of FIBC, inner liner, labels and document pockets.

- Design and performance requirements for FIBC, inner liners, labels and document pockets.

- Safe use of FIBC (including those with inner liners) within different locations defined for explosion endangered environments, described for locations where combustible dusts are, or can be, present, and for explosive gas locations.

- Procedures for type qualification and certification of FIBC, including the safe use of inner liners.

- Depending on their construction, the bags are classed as:

- Type A

- Type B

- Type C

- Type D

Restrictions around the usage of different bag types in Hazardous Locations is summarized in Table 16.6.3 of NFPA 77 “Use of Different Types of FIBCs”.

NFPA 77 2024ed Table 16.6.3 – Use of Different Types of FIBCs

| Bulk product in FIBC | Surroundings | ||

|---|---|---|---|

| MIE of Dust* | Non-Flammable Atmosphere | Class II, Division 1 and Division 2 (1000 mJ ≥ MIE > 3 mJ)* | Class I, Division 1 and Division 2 (Gas Group C and Group D) or Class II Division 1 and Division 2 (MIE ≤ 3mJ)* |

| MIE > 1000 mJ | A, B, C, D | B, C, D | C, D** |

| 1000 mJ ≥ MIE > 3 mJ | B, C, D | B, C, D | C, D** |

| MIE ≤ 3 mJ | C, D | C, D | C, D** |

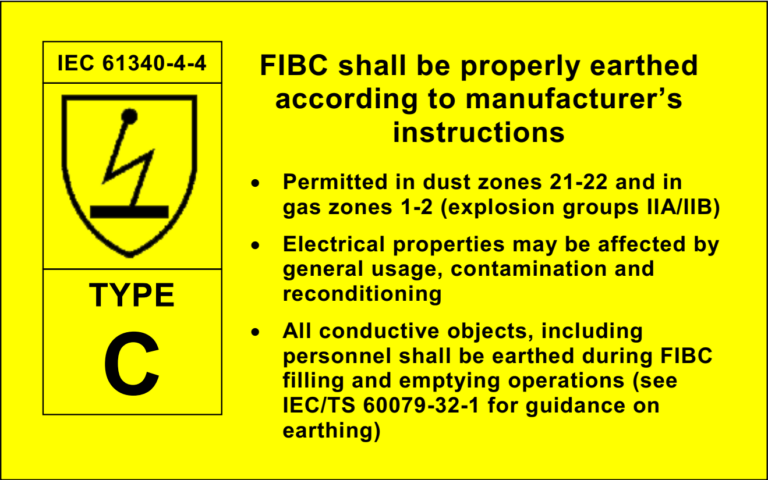

Type C bags

Type C bags, along with any inner liners incorporated into their construction, are designed to be grounded. This enables the dissipation of electrostatic charge from the bag so that incendive discharges from the bag are mitigated.

Type D bags are different from Type C bags in that they are constructed of a specific material that is designed to prevent incendive electrostatic discharges, hence do not require grounding. Additional specific requirements regarding the use of Type D bags are described in the standard.

NFPA 77 2024ed Section 16.6.6.1 states:

Type C FIBCs are constructed entirely from conductive material or insulating material that contains fully interconnected conductive threads or tapes with specific spacing. It is essential that Type C FIBCs be grounded during filling and emptying operations.

Clause 4.1.4 of IEC 61340-4-4 defines Type C bags as:

Type C FIBC are made from conductive fabric or plastic sheet, or interwoven with conductive threads or filaments and designed to prevent the occurrence of incendiary sparks, brush discharges and propagating brush discharges. Type C FIBC are designed to be connected to earth before the commencement of filling and emptying operations and remain connected to earth during these operations.

The maximum permissible resistance between the conductive/dissipative parts of the bag to the “designated earth bonding points” of the bag (also referred to as the “groundable point” in the standard) is limited to 1 x 108 Ω. One or more designated earth bonding points must be permanently attached to the bag. Bag lifting hooks should not rely on fortuitous metal connections to plant equipment, as they may have high-resistance protective coatings or product deposits that impede the dissipation of electrostatic charge from the bag. In addition, physical contact between the hooks and the plant equipment could be intermittent during the loading/unloading process.

The grounding system/device must be connected to the designated ground connection point/s.

It is for this reason that Earth-Rite® FIBC systems are supplied with two grounding clamps as standard.

With respect to liners used in Type C FIBC, there can be no reliance on “fortuitous” connections between the liner(s) and the static dissipative material from which the bag is constructed, emphasizing that the connections should be sufficiently strong to withstand the stresses caused by filling, transporting and emptying operations. Clause 5 of IEC 61340-4-4 outlines the combinations of Type C bags and inner liners that are permissible or not permissible for use in hazardous locations.

Attention is also drawn to the potential electrical isolation and electrostatic charging of conductive equipment like tools that could be left on, or near the Type C bag, such that it is difficult to determine if the tool is in good physical/electrical contact with the static dissipative parts of the bag (which should be grounded).

Type C bags and their ground connection points must have labels that enable their identification and correct specification.

As described on the label the standard highlights that repeated cycles of emptying, filling and cleaning, in addition to the potential contamination from other materials, could impair the electrical properties of the bag. It states that after a pre-determined number of cycles (consult the manufacturer) that the bags be tested in line with Clause 9 “Test Procedures” of IEC 61340-4-4.

The Earth-Rite® FIBC static grounding system provides a real-time check of the resistance through static dissipative material of the bag; however, this does not prove that all elements of the static dissipative material have not been damaged through physical or external material contact.

References to IEC TS 60079-32-1 “Explosive Atmospheres. Part 32-1: Electrostatic hazards, guidance” are made throughout the standard. As stated earlier, all aspects of this Technical Specification cannot be listed and should be purchased from an authorized seller. The primary points relating to FIBC are:

- Isolated conductive objects (e.g., tools, bolts, clips, etc.) should not be stored on, attached to, or even temporarily placed on any type of FIBC during filling and emptying operations. Even with Type C FIBC, the rough nature of some FIBC materials may prevent conductive objects placed on the FIBC from contacting the conductive elements in the fabric of the FIBC.

- In hazardous locations, all conductive objects within the immediate vicinity of any FIBC (i.e., less than about 1 m away) should be properly earthed during filling and emptying operations.

Newson Gale is not experts in HAZLOC assessments. The advice of an expert in carrying out HAZLOC assessments should be sought whenever there is doubt about the correct course of action in relation to HAZLOC operations.