Earth-Rite® MULTIPOINT II

Newson Gale’s single grounding system with eight independent active ground monitoring circuits

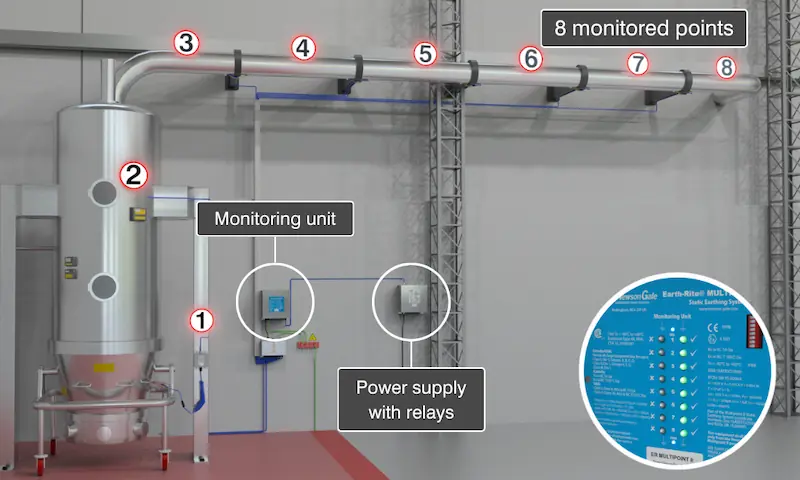

Eight ground monitoring circuits are provided in a single system.

Uses the highest level of intrinsically safe “ia” monitoring circuits which can be connected to equipment being used in Class I, II and III Division 1 locations, and dust groups.

Monitoring unit contains eight pairs of red and green LED indicators that inform operators of the ground status of the equipment requiring static grounding.

Operators do not need to interact with switches or resistance readings – the system will inform the operators on the equipment’s ground status as soon as the clamp or connector is attached to the equipment.

Utilizes a heavy-duty stainless-steel clamp, that combines sharp tungsten carbide teeth with a strong torsion spring to establish, and maintain, a positive connection to multiple components for the duration of the loading/unloading operation.

Grounding clamps with global certification that DO NOT contain any insulating materials (rubber handles/plastic) that exceed the volume or surface area for hazardous locations.

7 year warranty against manufacturer’s defects on PCBs.

1 year warranty on mechanical parts.

Actively monitors the resistance of the circuit between the connection to the metal objects and the verified ground point to a resistance of 10 ohms or less.

DOES NOT require calibration at installation or throughout its lifecycle.

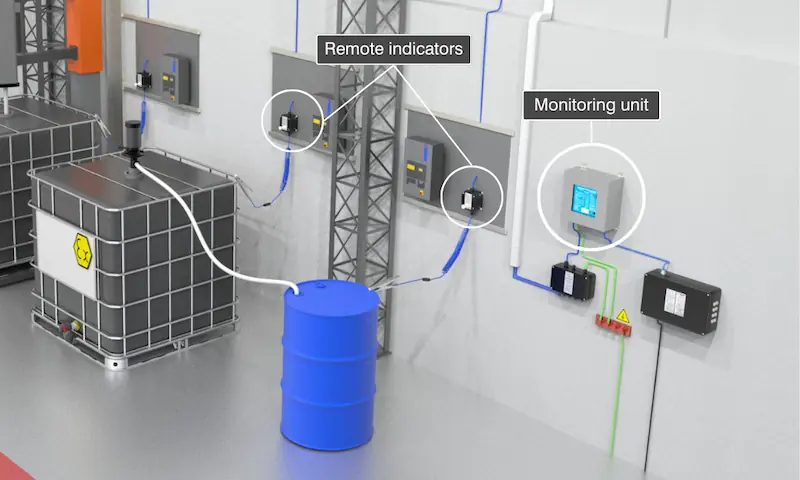

Optional remote indicator station can be located at points where the equipment to be grounded is outside the field of view of the monitoring unit.

Remote indicator stations utilize intrinsically safe circuits (ia) to power a static red or flashing green LED indicator and can be mounted in all Class and Division locations, and all gas and dust groups.

Datasheet Downloads

Learn more about Industry Standards and Guidelines relating to static electricity in explosive atmospheres:

- Gain insights into the specification of HAZLOC-certified equipment.

- Understand standards referenced in the industry.

- Learn about the selection of HAZLOC equipment.

- Evaluate competency requirements for personnel.

- Navigate HAZLOC equipment documentation.

cCSAus Certificates - United States

IECEx Certificates - International

ATEX Certificates - Europe

UKCA Certificates - United Kingdom

CCC Certificates - China

KCs Certificates - South Korea

P1 = one GRP enclosure | PSU = Power Supply Unit | MU = Monitoring Unit

Overview of the Earth-Rite® MULTIPOINT II

Since the first generation Earth-Rite® MULTIPOINT was launched in 2000, Newson Gale has supported customers on hundreds of applications with installation and application characteristics that challenged traditional “off the shelf” static control solutions.

The development of the MULTIPOINT evolved from our closeness to customers, which enabled our design engineers to identify the possibility of providing a single solution that combined active static ground monitoring and interlock capability to a range of applications that would otherwise have been prohibitive on the grounds of cost or installation difficulty. This level of flexibility was particularly relevant for pharmaceutical powder processing applications where multiple components could be potentially isolated from a verified ground.

Fast forward to 2016 and the release of the second generation of the Earth-Rite® MULTIPOINT II, which extended the multi-point grounding concept to a wider range of HAZLOC applications in both gas and dust atmospheres.

Eight active ground monitoring circuits in one system

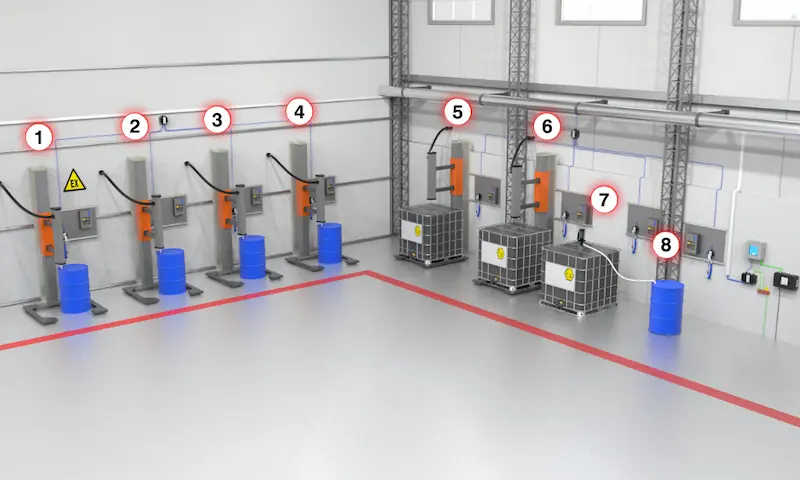

The Earth-Rite® MULTIPOINT II is a single grounding system that provides site operators with eight independent active ground monitoring circuits that can be used to monitor the ground status of eight discrete pieces of equipment used in hazardous locations. The monitoring unit consists of an array of eight pairs of green and red LEDs that indicate if the equipment is connected to a verified static grounding point.

The monitoring unit utilizes the highest level of intrinsically safe circuits HAZLOC ‘ia’ to allow for the connection to equipment in locations classified as Class I, II, and III Division 1 (covering all gas, vapor, and dust groups). This removes any doubt regarding the location or existence of a Classified atmosphere at the point(s) where the Earth-Rite® MULTIPOINT II is connected to equipment. Temporary and semi-permanent connections can be made with a range of 2-core grounding clamps and connectors.

The monitoring circuit requires a resistance of 10 ohms or less before it will indicate a permissive condition to the operator supervising the procedure.

A simple traffic light method of “GO/NO GO” red and green LED indication provides process operators with a simple means of knowing that they can continue with the next step in their production process.

10 ohms is a benchmark resistance threshold defined in multiple best practice industry guidelines for the control of static electricity in hazardous locations. If the output contact driven by the corresponding monitoring circuit is active, and the ground status condition is permissive, a dry/volt-free SPDT relay will be energized.

The monitoring unit is connected to equipment in the hazardous location via marshalling boxes that route the monitoring circuits to the points at which the system will be connected to the equipment requiring static grounding. If the equipment is in a position where it is difficult for operators to see the main LED array on the face of the monitoring unit, additional remote indicator stations mounted at the point of connection can be specified.

The remote indicator stations, fitted with a pair of red and green LED indicators, can be mounted in Class I, II, and III Division 1 locations and all gas and dust groups. The LEDs are powered by intrinsically safe HAZLOC ‘ia’ circuits with their enclosures classified as simple apparatus. When the Earth-Rite® MULTIPOINT II detects a connection resistance of 10 ohms or less to the equipment, the LEDs on the remote indicator station switch from red to flashing green. The flashing effect demonstrates that the Earth-Rite® MULTIPOINT II is continuously monitoring the ground circuit for the equipment requiring electrostatic grounding.

The channels for each monitoring circuit can be activated or deactivated via a set of DIP switche(s) located on the front panel inside the monitoring unit.

Multiple interlocking combinations

Intrinsically safe (IS) power is delivered to the monitoring unit by the power supply unit, which can be installed in a Class I, II, and III Div 2 location or a local non-hazardous location. The power supply unit also provides the dry/volt-free relays, which can be connected to external equipment like PLCs controlling the process or electromechanical equipment that can be activated/deactivated by the interlocks.

Each of the eight monitoring circuits has its own dedicated relay. This type of setup is particularly useful for multi-loading/unloading facilities, e.g., railcar loading terminals, that have PLCs controlling specific pump metering systems dedicated to the loading of each railcar.

If the specifier wishes to control external equipment, e.g., a single pump, that requires multiple pieces of equipment to be connected to ground prior to equipment activation, the relevant monitoring circuit can be “grouped” via a DIP switch located inside the power supply unit. For example, if a pump feeding three drums requires all drums to be grounded prior to filling, the relevant channels, e.g., 1, 2, and 3, can be grouped so that these circuits require a connection resistance of 10 ohms or less prior to the pump being activated.

All of the monitoring circuits can be grouped if the specifier wishes to control the process so that processing cannot take place, e.g., a fluid bed dryer system, unless all potentially isolated components are connected to ground.

Communication between the monitoring unit and power supply unit is provided via CAN-bus.

Specification support

Wherever possible, we recommend that our hazardous locations trained engineers review your application and installation objectives prior to quotation.

If you are unsure about the installation of the Earth-Rite® MULTIPOINT II, our hazardous location experienced engineers will be more than happy to support.

Reliability

The controller on the monitoring unit features self-checking Watchdog technology. A detected, channel-specific, hardware fault will put that channel’s relay into its non-permissive state. The fault will be visually indicated by a flashing red LED. Detected critical system errors that affect all monitoring channels are visually indicated on the Watchdog LED and will put all monitoring channel relays into their non-permissive states.

The coding for the microcontroller is written in MISRA C, a widely accepted protocol in many industries.

The Watchdog timer circuit detects potential faults with the program driving the microcontroller. A blue flashing LED, located on the monitoring unit, indicates when the Watchdog timer circuit is actively monitoring the functionality of the software.

Should there be a communication error between the monitoring unit and the power supply unit, the fault relay will switch state.

Please note that a HAZLOC-qualified person is required to carry out the installation of HAZLOC-certified products, as per the product manual. If you have any doubts with respect to the installation requirements of Newson Gale equipment in hazardous locations, one of our hazardous location experienced engineers will be happy to support you.

Request a live product demo

Newson Gale has an extensive product range that can be tailored to your processes and the range of HAZLOC classifications at your location.

The most effective way to identify what is applicable for your operations is by speaking with our team. They will provide in-depth information on the products, features and how the range of options can be tailored to your needs.