Earth-Rite® II RTR

Newson Gale’s dedicated tanker truck static grounding system with system interlocks and visual indication

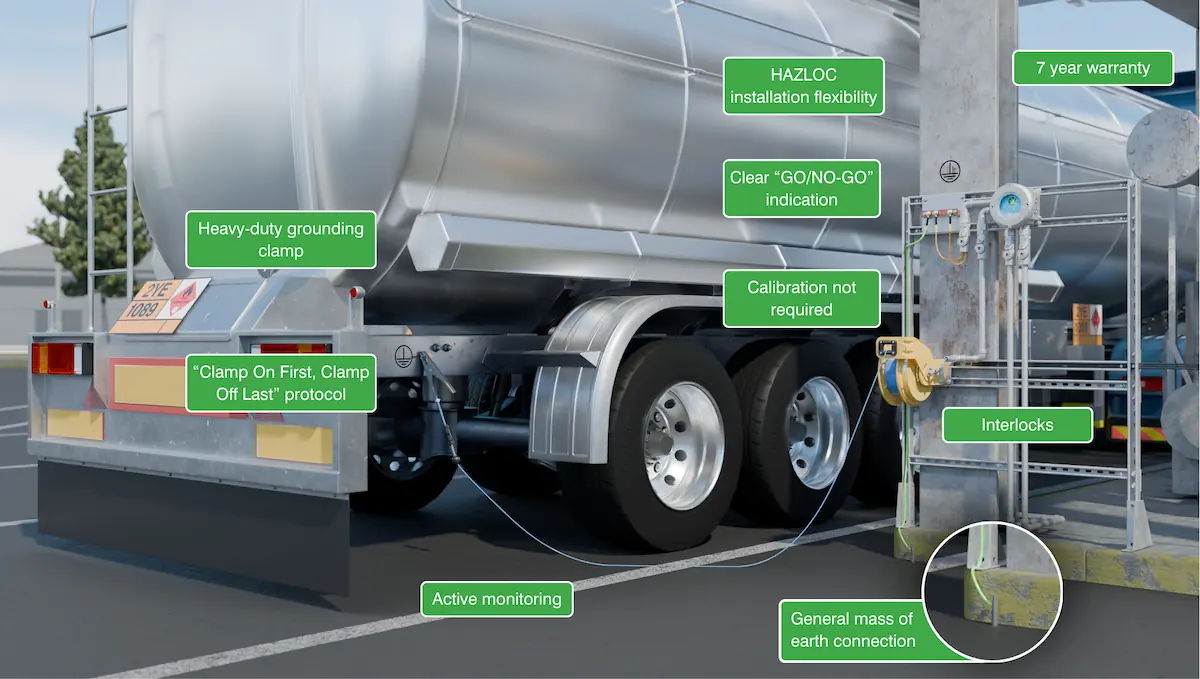

Actively monitors the resistance of the circuit between the connection to the tanker truck and the loading gantry’s designated grounding point to 10 ohms resistance or less.

DOES NOT require calibration at installation or throughout its lifecycle.

Utilizes a heavy-duty stainless-steel clamp, that combines sharp tungsten carbide teeth with a strong torsion spring to establish, and maintain, a positive connection to the tanker truck for the duration of the loading/unloading operation.

Grounding clamps with global certification that DO NOT contain any insulating materials (rubber handles/plastic) that exceed the volume or surface area for hazardous locations.

7 year warranty against manufacturer’s defects on PCBs.

1 year warranty on mechanical parts.

Unlike many grounding systems that claim to detect the capacitance of the tanker truck, the Earth-Rite® II RTR grounding system stands out by eliminating the need for calibration during installation or throughout its service life. This saves labor time and cost while reducing the risk of delays in truck loading operations.

Datasheet Downloads

Learn more about Industry Standards and Guidelines relating to static electricity in explosive atmospheres:

- Gain insights into the specification of HAZLOC-certified equipment.

- Understand standards referenced in the industry.

- Learn about the selection of HAZLOC equipment.

- Evaluate competency requirements for personnel.

- Navigate HAZLOC equipment documentation.

cCSAus Certificates - United States

IECEx Certificates - International

InMetro Certificates - Brazil

ATEX Certificates - Europe

UKCA Certificates - United Kingdom

PESO Certificates - India

CCC Certificates - China

KCs Certificates - South Korea

P1 = one GRP enclosure

Static Grounding for Tanker Truck Transfer Operations

The Earth-Rite® II RTR is specifically engineered to detect the capacitance of tanker trucks, offering reliable grounding throughout loading and unloading processes.

Why Choose the Earth-Rite® II RTR?

- Specialized for Tanker Trucks: Detects and grounds tanker trucks to 10 ohms or less, minimizing HAZLOC risks.

- Tri-Mode Technology: Ensures the system only permits product transfer when all three safety parameters (tanker recognition, verified ground, and continuous low-resistance connection) are confirmed

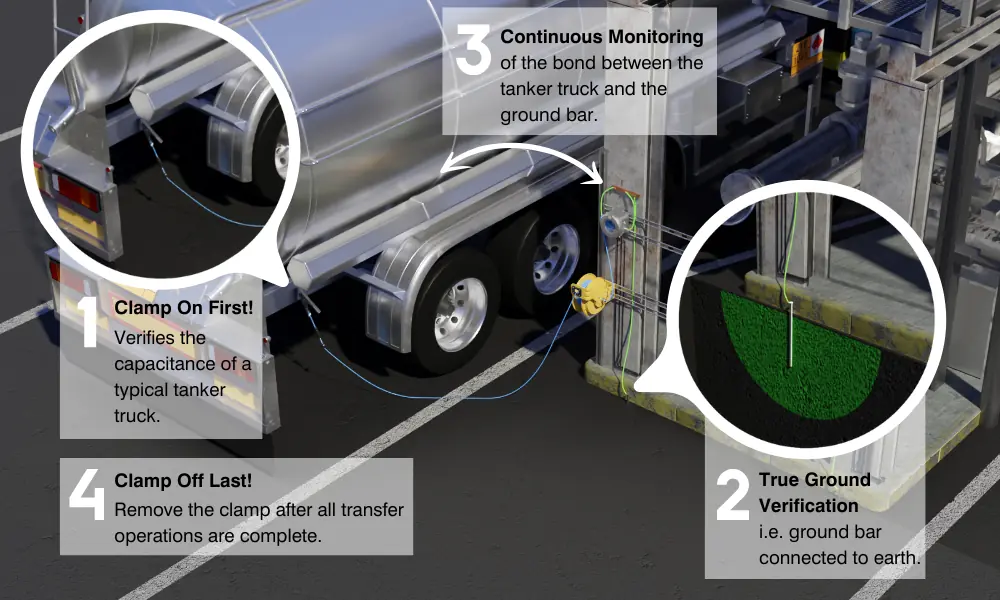

Remember to always follow a “Clamp On First, Clamp Off Last” protocol by attaching the grounding clamp before starting any operation, and keep it connected until all transfer activities are complete.

Overview of the Earth-Rite® II RTR

The Earth-Rite® II RTR forms part of the Earth-Rite® range and is designed to ground a tanker truck/tank truck during loading and unloading operations. Because tanker trucks are isolated from the general mass of the earth by their tires, they can accumulate electrostatic charge during the loading/unloading of electrically insulating materials. Because the tanker trucks are electrically isolated from the earth, it has a capacitance relative to the earth.

A simplified model of tanker truck capacitance is the parallel plate capacitor, and tanker trucks are generally thought to have a capacitance value of greater than 1000 picofarads (pF).

Newson Gale’s own research into tanker truck capacitance shows high variations of capacitance depending on several variables. It is for this reason that the Earth-Rite® II RTR, via its patented method of operation, can cater for such variables, thus eliminating the need to calibrate the systems at the point of installation or throughout its period in use.

Operation of the Earth-Rite® II RTR

To help promote the standard operating procedure (SOP) of “Clamp On First, Clamp Off Last” the Earth-Rite® II RTR sends an intrinsically safe Ex ia signal via the grounding clamp’s connection to the designated grounding point on the tanker truck, whereby it determines if the capacitance reflects that of a tanker truck.

(All other metal objects in the local gantry area should be grounded for electrical fault protection, lightning protection, and the elimination of electrostatic ignition sources within hazardous locations.)

The signal completes its journey to the Earth-Rite® II RTR via the general mass of the Earth and the loading gantry’s designated grounding point. If the signal returns to the Earth-Rite® II RTR, the system can verify if the designated grounding point at the loading gantry is connected to the general mass of the earth. Electrostatic charge generated by the process will transfer from the tanker truck via the Earth-Rite® II RTR to earth.

When the Earth-Rite® II RTR checks that the designated grounding point of the loading gantry has a connection to earth, it then switches to active monitoring of the clamp’s connection between the tanker truck and the designated grounding point of the loading gantry. In line with NFPA 77 2024ed “Recommended Practice on Static Electricity” where 10 ohms or less is cited as a guidance electrical resistance threshold for metal equipment requiring static grounding or bonding in hazardous locations using copper wire, which is often found in grounding systems.

An important point to note is that the Earth-Rite® II RTR not only monitors the grounding clamp’s connection to the tanker truck, but it also actively monitors its connection to the designated grounding point of the loading gantry. Connection to earth via a local designated earth point and not via a high integrity electrical earth is possible due to the intrinsically safe circuit concept being achieved through ‘galvanic isolation’.

When the necessary inputs are in place, the Earth-Rite® II RTR switches from solid red to flashing green LED indication. Site operators have the option of using either intrinsically safe or volt-free non-intrinsically safe contacts to interlock with the equipment controlling the transfer of material. These can be utilized to prevent the loading/unloading process from starting unless a permissive state is provided by the Earth-Rite® II RTR.

Please note that a HAZLOC-qualified person is required to carry out the installation of HAZLOC-certified products, as per the product manual. If you have any doubts with respect to the installation requirements of Newson Gale equipment in hazardous locations, one of our hazardous locations experienced engineers will be happy to support you.

Request a live product demo

Newson Gale has an extensive product range that can be tailored to your processes and the range of HAZLOC classifications at your location.

The most effective way to identify what is applicable for your operations is by speaking with our team. They will provide in-depth information on the products, features, and how the range of options can be tailored to your needs.