Large Size Heavy-Duty Static Grounding Clamp

Intrinsically safe dual core static grounding clamp

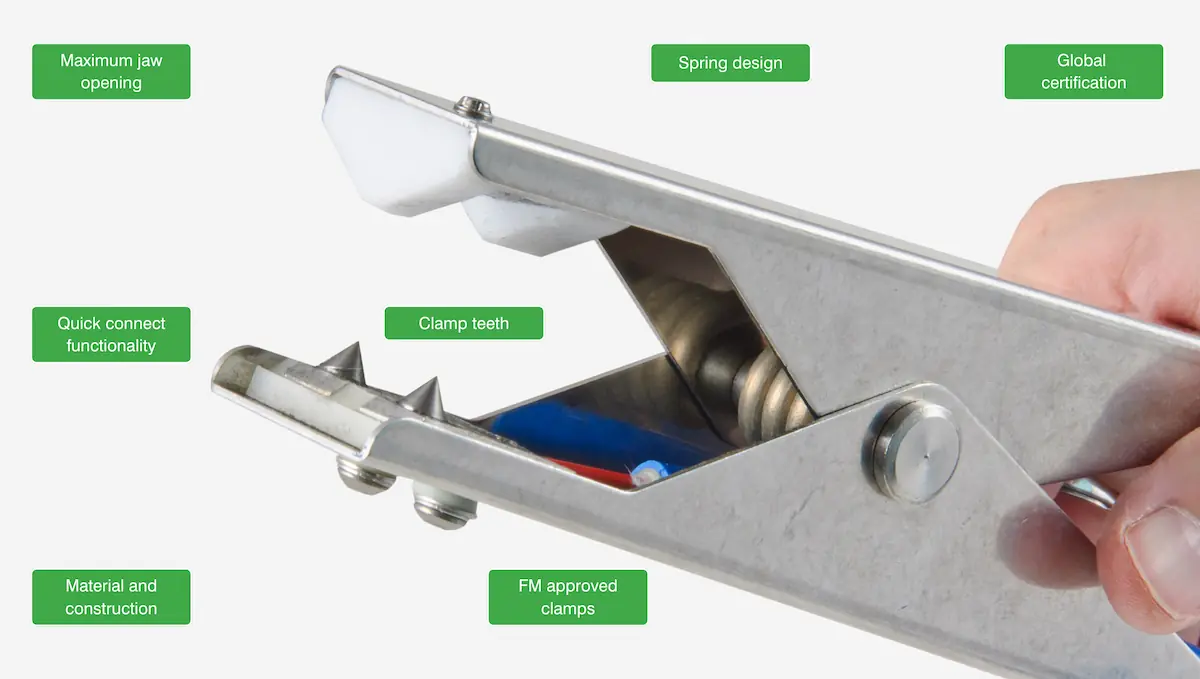

1.18” (30 mm) approx.

Purpose designed spring providing a robust and reliable clamp pressure.

IECEx, ATEX, UKCA and FM approved.

Quick connect functionality for easy removal out of the hazardous location.

FM approved clamps tested for:

- Clamp Pressure – ensuring the grounding clamp is capable of establishing and maintaining low resistance electrical contact with equipment.

- Electrical Continuity – ensuring the electrical continuity from the teeth throughout the grounding clamp is less than 1 ohm.

- High Frequency Vibration – ensures the grounding clamp is capable of maintaining positive contact when attached to vibrating equipment.

- Mechanical Pull Test – ensures the grounding clamp cannot be pulled off the equipment.

The clamp is made from heavy-duty 304 grade stainless-steel. It has a pair of extra sharp teeth made from tungsten carbide which is known for its superior durability. When paired together in one solution, it provides a high degree of clamp stability which can bite through rust, paint coatings, and deposits of process material with ease.

Learn more about Industry Standards and Guidelines relating to static electricity in explosive hazardous locations:

- Gain insights into the specification of HAZLOC certified equipment.

- Understand standards referenced in the industry.

- Learn about the selection of HAZLOC equipment.

- Evaluate competency requirements for individuals.

- Navigate HAZLOC equipment documentations.

IECEx Certificates - International

ATEX Certificates - Europe

UKCA Certificates - United Kingdom

Overview of the VESX90-IP dual core large size heavy-duty static grounding clamp

The VESX90-IP static grounding clamp can be installed with the Bond-Rite® and Earth-Rite® systems to provide interlock control and visual indication to verified ground connection points and offer the highest levels of protection over electrostatic ignition risks.

Newson Gales’ approved dual core heavy-duty static grounding clamps enable positive contact with the equipment to be grounded.

When flammable or combustible products are being handled and processed in hazardous locations, it is essential to specify certified equipment that will protect personnel from sources of electrostatic ignition.

Why choose our VESX90-IP large size heavy-duty clamp?

Static grounding clamps that combine Factory Mutual (FM), ATEX, and IECEx approvals are rigorously tested and certified to ensure they are capable of dissipating static charges from potentially charged equipment.

This is especially significant when the equipment can be covered in coatings, product deposits, or rust that is capable of preventing the clamp from making low resistance electrical contact with the equipment to be grounded.

- Tungsten carbide teeth to bite through paint deposit build up

- Quick connect functionality for easy removal out of hazardous location

- Monitors up to 10 ohms or less

- Can be integrated into the Earth-Rite® and Bond-Rite® systems to ensure a true verified ground connection

What are the benefits of using tungsten carbide teeth?

Tungsten carbide is one of the hardest materials in use in industry today, and when used in combination with a well-designed clamp spring, it has the capability to continuously bite through coatings, rust, or product deposits that a basic alligator clip or welding clamp would struggle with.

Sharpened tungsten carbide teeth are a standard feature of Newson Gale’s heavy-duty clamps.

Why is spring design so important?

A grounding clamp’s effectiveness at protecting against the ignition of flammable atmospheres should not be judged by how difficult it is to open the clamp handles – that is the result of a poorly designed spring and clamp assembly.

A well-designed spring and clamp assembly should enable an operator to apply a reasonable amount of torque to open the clamp without causing stress to their hand.

The most critical factor to understand is the pressure applied at the point of contact. This is where the clamp teeth establish a secure electrical connection with the equipment susceptible to static charging.

The combination of spring material, spring diameter, the number of active spring coils, and the length of the spring legs has all been factored into Newson Gale grounding clamps to balance operator ergonomics with a clamping force that can exceed the testing requirements of Factory Mutual (FM).

5 good reasons to specify ATEX, IECEx, UKCA and FM approved clamps

- Clamp Pressure Testing – ensures the grounding clamp is capable of establishing and maintaining low resistance electrical contact with equipment (FM approvals).

- Electrical Continuity Testing – ensures the electrical continuity from the teeth throughout the grounding clamp is less than 1 ohm (FM approvals).

- High Frequency Vibration Testing – ensures the grounding clamp is capable of maintaining positive contact when attached to vibrating equipment (FM approvals).

- Mechanical Pull Testing – ensures the grounding clamp cannot be pulled off the equipment without an intentional application of force (FM approvals).

- Sources of Mechanical Sparking – ensures no mechanical sparking sources are present in the clamp (IECEx/ATEX certification).

Request a live product demo

Newson Gale has an extensive product range that can be tailored to your processes and the range of HAZLOC classifications at your location.

The most effective way to identify what is applicable for your operations is by speaking with our team. They will provide in-depth information on the products, features and how the range of options can be tailored to your needs.