Earth-Rite Static Grounding System Range

Static grounding and interlock systems

What is an Earth-Rite® static grounding system?

Earth-Rite systems provide specialized static grounding solutions for HAZLOC operations, offering safe dissipation of static electricity during material transfer processes.

| Model | Applications | Key Feature |

|---|---|---|

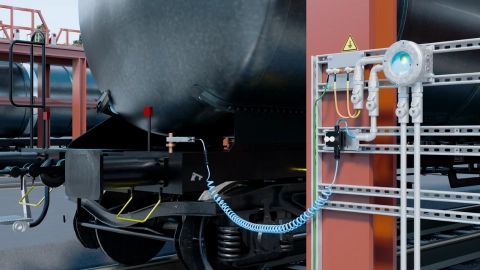

| Earth-Rite® RTR | Tankers, trucks & road tankers | Continuously monitors the connection between the tanker & grounding point |

| Earth-Rite® MGV | Vacuum trucks | Mobile truck-mounted static grounding system |

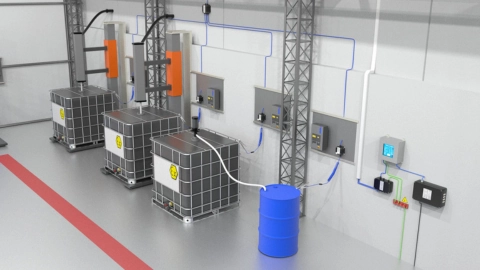

| Earth-Rite® PLUS | Railcars, Ex IBCs, skids, totes & drums | Flexible static grounding for various objects |

| Earth-Rite® DGS | Railcars, Ex IBCs, skids, tanker trucks & drums | Dual static grounding for two items |

| Earth-Rite® FIBC | Type C FIBC bags | Dedicated Type C FIBC static grounding system |

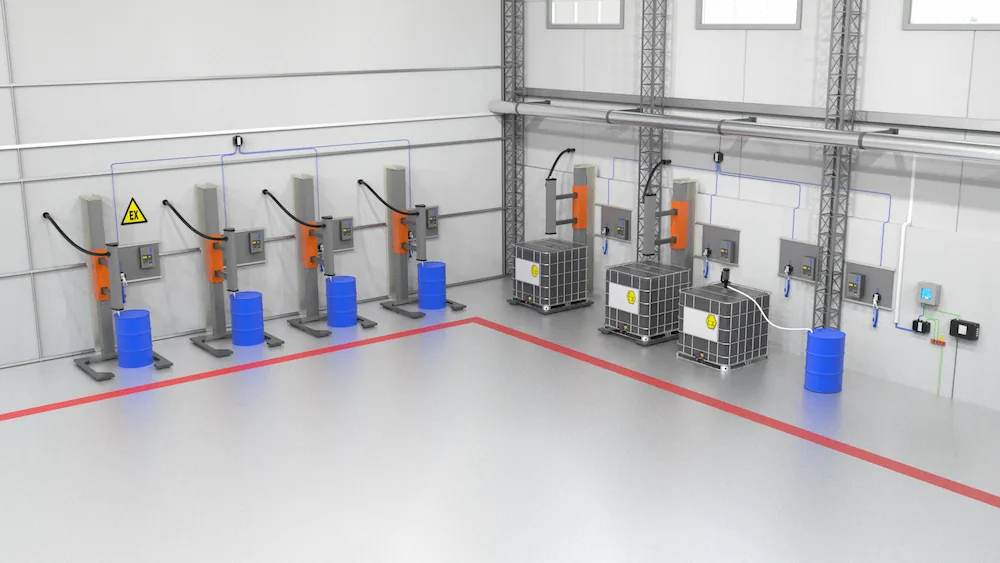

| Earth-Rite® MULTIPOINT | General grounding in a factory or plant setting | Single grounding system with eight independent active ground monitoring circuits |

How does the Earth-Rite® grounding system work?

All of our Earth-Rite® systems contain proven electronics that have provided features for users for many years. Some of these features include:

- Monitoring of the resistance between metallic equipment requiring static grounding protection and the site’s designated grounding point.

- Three high intensity flashing green LED indicators for operator visual verification.

- Internal dry contacts that can automatically control the flow of product or additional attention-grabbing devices.

- Earth-Rite® systems also have an option to switch an intrinsically safe signal or power supply.

Ground Verification

The Earth-Rite® RTR and Earth-Rite® MGV systems detect the capacitance of a typical tanker truck/tank truck and provide true earth ground verification.

Continuous Monitoring

Continuous monitoring of metallic objects with a 10 ohms or less resistance connection to the verified ground point.

Interlock for Process Control

Ensures a permissive condition for interlocked equipment when a ground connection is established, therefore reducing potential human error.

Grounding Clamps

FM/IECEx/ATEX-approved heavy-duty grounding clamps to ensure a good connection to the metal object through paint, rust, and product deposits.

What is the difference between grounding and bonding?

Grounding requires a physical connection to earth via a circuit, whereas bonding does not require a physical connection to the earth.

What is static grounding?

Static grounding clamps/systems bond the object to ground. Grounding systems are designed so that the static charge generated on the object has a path to Earth. This is a requirement for facilities operating within hazardous locations, protecting personnel and plant assets from explosions or fires.

What is static bonding?

Bonding equalizes the charge on two metal objects by connecting them together.

What is an interlock system?

Interlock devices allow the system to automatically control the process if the connection to the verified ground point. They require certain actions to be carried out in a specific sequence. This assists in reducing potential human error and helps keep plant workers safe during loading/unloading processes, and mitigating the risk of accidents.