Earth-Rite® PLUS

Newson Gale’s flexible active static grounding system

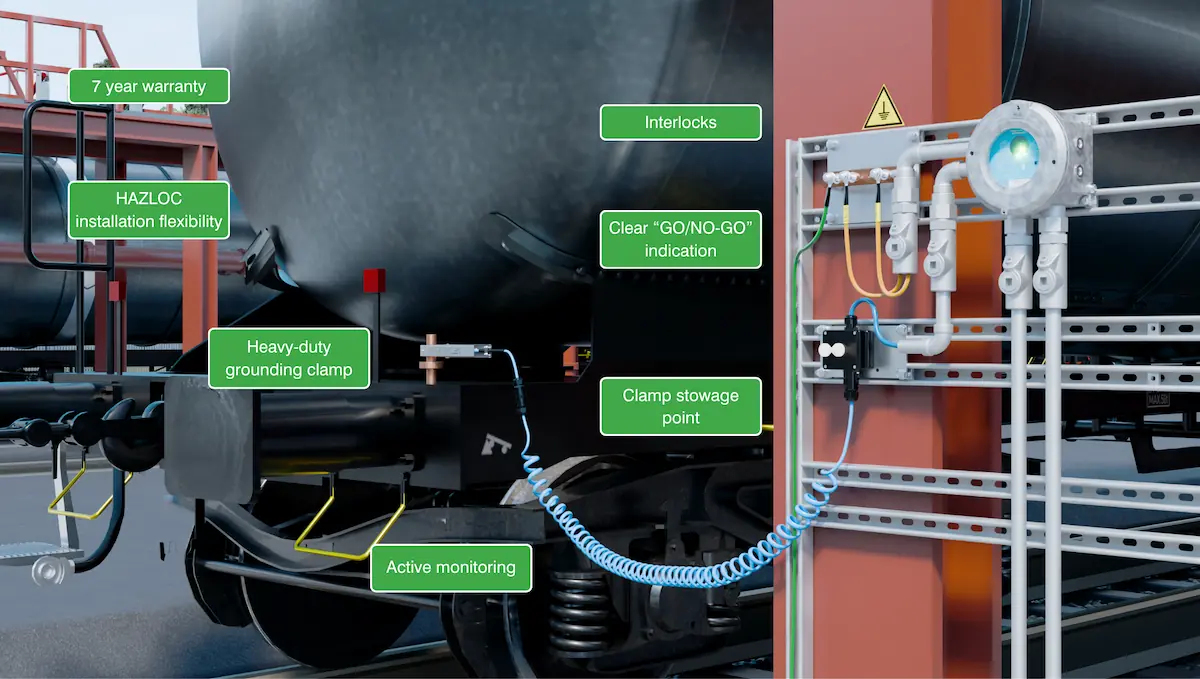

Actively monitors the resistance of the circuit between the connection to the rail tanker and the loading gantry’s designated earthing point to 10 ohms or less.

DOES NOT require calibration at installation or throughout its lifecycle.

Utilizes a heavy-duty stainless-steel clamp, that combines sharp tungsten carbide teeth with a strong torsion spring to establish, and maintain, a positive connection to the rail tanker for the duration of the loading/unloading operation.

Grounding clamps with global certification that DO NOT contain any insulating materials (rubber handles/plastic) that exceed the volume or surface area for hazardous locations.

7 year warranty against manufacturer’s defects on PCBs.

1 year warranty on mechanical parts.

Learn more about Industry Standards and Guidelines relating to static electricity in explosive atmospheres:

- Gain insights into the specification of HAZLOC-certified equipment.

- Understand standards referenced in the industry.

- Learn about the selection of HAZLOC equipment.

- Evaluate competency requirements for personnel.

- Navigate HAZLOC equipment documentation.

cCSAus Certificates - United States

IECEx Certificates - International

InMetro Certificates - Brazil

ATEX Certificates - Europe

UKCA Certificates - United Kingdom

CCC Certificates - China

KCs Certificates - South Korea

PESO Certificates - India

P1 = one GRP enclosure

Discover the Earth-Rite® II PLUS

Watch as we explore the Earth-Rite® II PLUS, a highly adaptable active ground monitoring system designed to ground various metal objects in explosive HAZLOC atmospheres. The Earth-Rite® II PLUS is ideal for grounding of, but not limited to:

- Metal drums

- Railcars

- Metal frames of EX IBCs

- Pump metering skids

Overview of the Earth-Rite® II PLUS

The Earth-Rite® II PLUS is a flexible active ground monitoring system that enables the static grounding of a wide range of metal ‘objects’ approved for use in all classified hazardous locations. Such objects include, but are not limited to:

- Metal totes and drums

- Railcars

- Metal frames of EX IBCs

- Pump metering skids

In line with recommended practice, it is advisable that plant operators follow a simple protocol of “Clamp On First, Clamp Off Last” (CoF/CoL). This should, wherever possible, be incorporated into the process operators’ SOP.

Operation of the Earth-Rite® II PLUS

To help minimize interaction with complex system interfaces, the process operator does not need to interact with any settings or interpret any readings on the Earth-Rite® II PLUS system. By simply attaching the grounding clamp of the Earth-Rite® II PLUS to the object requiring static grounding, the system will automatically determine if the connection resistance to the object is 10 ohms or less. It achieves this by passing an intrinsically safe signal via the clamp teeth into the base metal of the object. If a connection resistance of 10 ohms or less is achieved, the signal returns to the Earth-Rite® II PLUS where the circuit electronics register a permissive condition.

An important point to note is that the Earth-Rite® II PLUS not only monitors the grounding clamp’s connection to the object, it also actively monitors its connection to the designated grounding point of the plant. Connection to earth via a local designated ground point and not via a high integrity electrical earth is possible due to the intrinsically safe circuit concept being achieved through ‘galvanic isolation’.

When the necessary inputs are in place, the Earth-Rite® PLUS switches from a solid red “NO-GO” to a flashing green “GO” LED indication. Site operators have the option of using either intrinsically safe or dry/volt-free, non-intrinsically safe contacts to interlock with the process equipment. This can be utilized to prevent the process from beginning unless a permissive state is provided by the Earth-Rite® II PLUS.

Please note that in an emergency shutdown scenario product may continue to move or flow after the equipment has been shut down. This could lead to the accumulation of static electricity on the object requiring static grounding if the grounding clamp has been disconnected. If a HAZOP assessment highlights the potential for such a scenario to occur, additional measures may need to be put in place. For example, it may be possible to determine the charge relaxation time of the material and issue an SOP to operators so that they do not approach the equipment/object during the specified time period. Site operators should retain the services of a static control consultant if this scenario could arise.

Clamp penetration

The operations listed above often result in equipment being covered in product deposits, thick protective coatings, rust, or the build-up of dirt/grime over a sustained period of time. In order to achieve a resistance of 10 ohms or less connection, it is crucial that the grounding clamp be capable of penetrating such layers in a repeatable, robust, and reliable way. It is for this reason that Newson Gale pioneered the use of the hard-wearing metal tungsten carbide to produce teeth capable of penetrating connection inhibitors like product deposits, paint coatings, rusted surfaces, etc.

The sharpened profile of the teeth, used in combination with a strong spring housed in a heavy-duty stainless steel body, enables their repeated use in harsh industrial environments. Not only are strong initial connections made to the equipment, but they are also maintained for the duration of the material-handling process.

Intrinsic safety (IS)

It can be difficult to determine the boundaries between Division 1 and Division 2 classified locations, particularly in drum/IBC mixing and filling operations. This is why you will benefit from our certified grounding clamps, approved for use in all classified hazardous locations.

The grounding clamps have been tested and approved for:

- Clamp Pressure – ensuring the grounding clamp is capable of establishing and maintaining low resistance electrical contact with equipment.

- Electrical Continuity – ensuring the electrical continuity from the teeth throughout the grounding clamp is less than 1 ohm.

- High-frequency Vibration – ensures the grounding clamp is capable of maintaining positive contact when attached to vibrating equipment.

- Mechanical Pull Test – ensures the grounding clamp cannot be pulled off the equipment without the intentional application of force.

Installation of the Earth-Rite® II PLUS

Simple wall-mounted enclosures complemented by straightforward cabling and PCB system wiring requirements. Flexible HAZLOC enclosure options and power supplies which can run off either 115v/230v AC and 12v/24v DC. The Earth-Rite® II PLUS is simple to install and operate. The unit is designed to operate “out of the box”. No required calibration at the point of installation nor throughout its time in use.

The XP/Ex d flameproof and dust-certified enclosure can be installed in all gas/dust groups, in Class I, II, and III Div 1 and 2 locations.

Can be installed in all Classified Hazardous Locations, Class I Div 1 liquid and vapor groups A, B, C, D (including hydrogen group B) and powder groups E, F & G, and all Class III locations.

The grounding clamp can be supplied with a range of spiral cable lengths or a 50 ft (15 m) 2-core straight cable on a retractable reel.

Please note that a HAZLOC-qualified person is required to carry out the installation of HAZLOC-certified products, as per the product manual. If you have any doubt with respect to the installation requirements of Newson Gale equipment in hazardous locations, one of our hazardous location experienced engineers will be happy to support you.

Request a live product demo

Newson Gale has an extensive product range that can be tailored to your processes and the range of HAZLOC classifications at your location.

The most effective way to identify what is applicable for your operations is by speaking with our team. They will provide in-depth information on the products, features and how the range of options can be tailored to your needs.