Technical Article

Hydrogen Safety

Case Studies

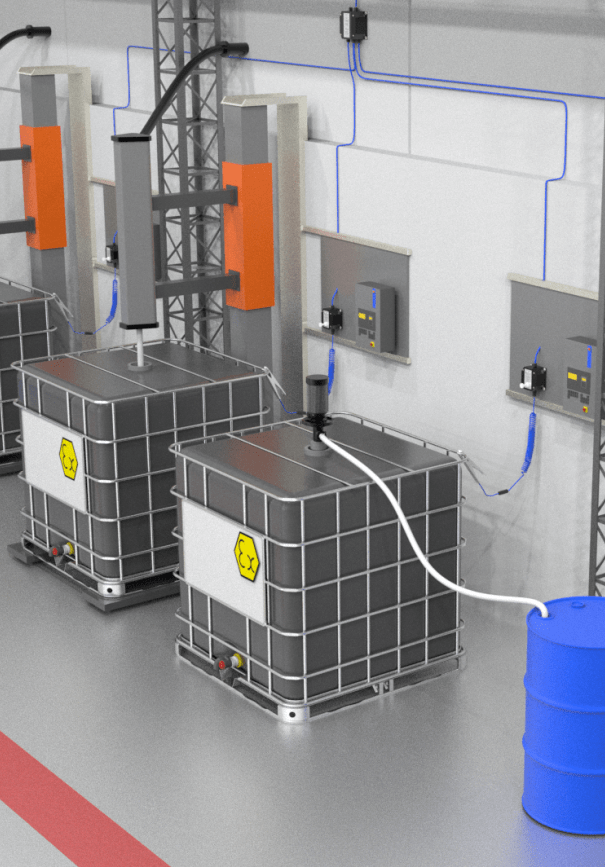

Storing and Handling Flammable Liquids Safely

Application Spotlight

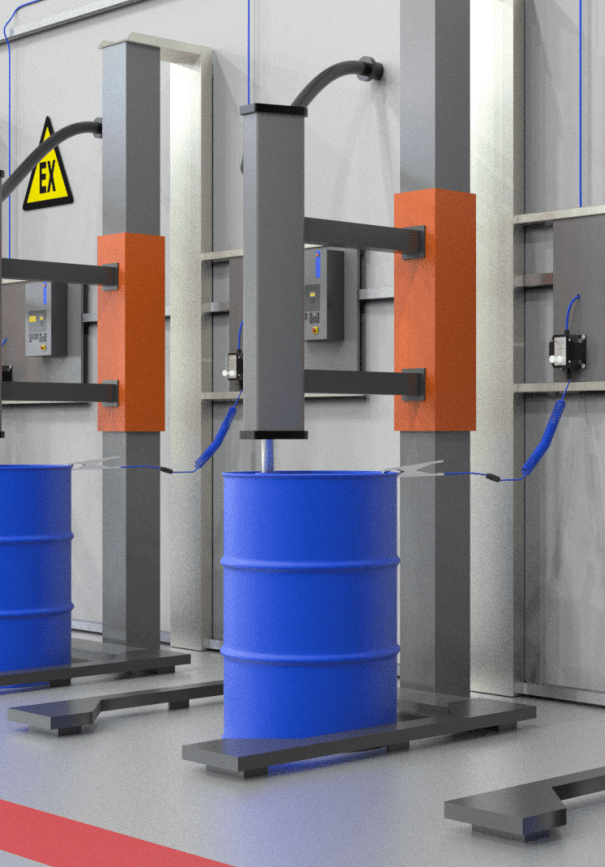

Grounding Multiple Metal Containers

Technical Article

Resistance Vs Impedance Vs Capacitance

Videos

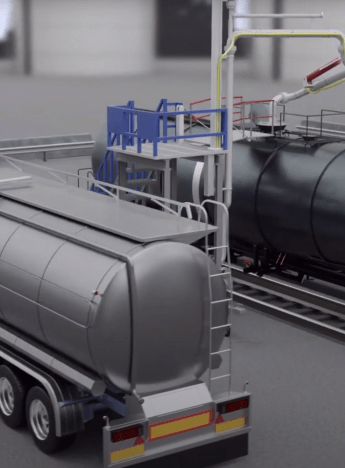

Earth-Rite® DGS Animation

Applications Handbook

Grounding & Bonding Applications Handbook

Technical Article

New Innovation in Static Grounding Protection

Technical Article

Specifying a HAZLOC/EX static control solution

Technical Article

Passive or Active Grounding

Technical Article

Static Ignition Risks of Drum Filling

Technical Article

Earth-Rite DGS Transloading Operations

Case Studies

Risk of Electrostatic Ignition during Storage Tank Cleaning Operations